The West Yorkshire town of Huddersfield is situated at the convergence of the rivers Colne and Holme. Inhabitants of these river valleys discovered that the water – which flows from the Millstone Grit Pennine hills – gave excellent results for the washing of raw wool.

And so the wool textile industry was born. The industry was traditionally cottage based, with spinning and weaving often taking place in the same dwelling. Many of the workers operated from smallholdings, supplementing their income with the manufacturing of wool textiles. The finished cloth they produced was then sold through merchants who regularly attended the town’s Cloth Hall. But then came the industrial revolution of the 19th Century, bringing with it great change and unrest to these valleys as the wool textile industry became mill based and mechanised.

Market Place Huddersfield

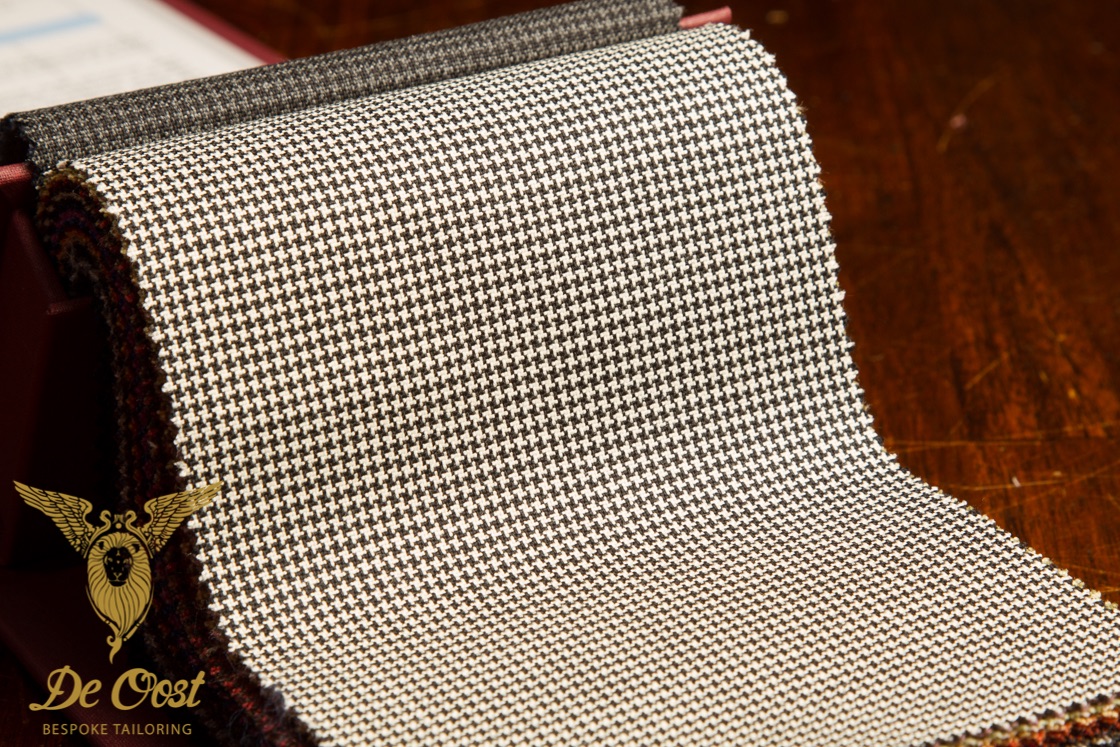

This led to troubled times as large-scale mill production took over and, due to the scale of industrialisation, virtually all the valleys’ inhabitants were left with little option but to take their skills into the mills. They undertook the processes of scouring, carding, spinning, weaving, dyeing and finishing as many of the mills were totally vertical and carried out all processes.

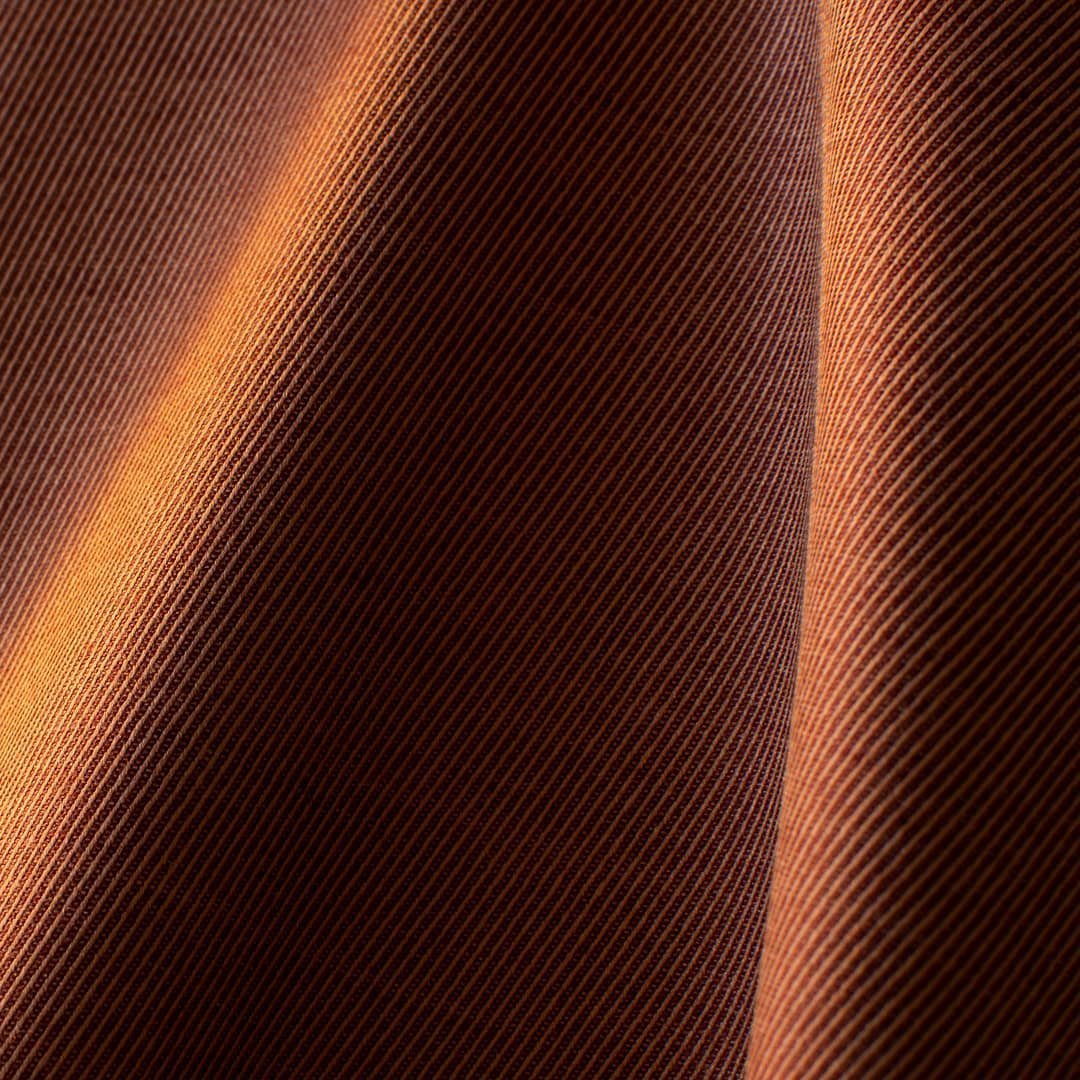

Manufacture of these fine fabrics demanded a high level of expertise and Huddersfield quickly became synonymous with fine woollen and later, fine worsted cloth manufacture. The name ‘Made in Huddersfield, England’ became a highly revered global brand, which appeared on the selvedges of many fabrics worldwide. These high quality fabrics were the choice of Kings and Princes alike. The woollen industry has profoundly influenced the course of English history since the 14th century. Today – with all the results of technological achievement throughout the world influencing our lives, woollen and worsted cloth is still regarded as the ideal clothing by most people living in moderate and cool countries.

Textile Mill 1920's

Today, as in years past, the British, ade in Huddersfield label is linked with the best in woollen and worsted cloth, and carries a cachet which is indisputable. The provision of woollen coverings, firstly in the form of raw wool and later in clothes, has been a trade of great importance in England for more than 600 years. Even today the Lord Chancellor of England sits in the House of Lords on a woolsack- a reminder of the fact it was wool which first bought prosperity to England in the Middle Ages. Magnificent churches and gracious houses can be seen in many parts of England, even in quiet small villages, which owe their existence to the wool and cloth trade.

The cloth manufacturers are also responsible for many of the names by which Englishmen are known, for instance, Weaver, Walker, Fuller and Dyer. An unmarried woman is still known as a spinster. Although the methods of converting raw wool into cloth have changed vastly over the years, with the introduction of new forms of power and new types of machinery, it still remains an industry in which the individual craftsman is of great importance. It is also an industry mainly in the hands of long established companies with years of experience and tradition behind them. Fine woollen and worsted manufacture became a Huddersfield tradition, with skills and expertise handed down from generation-to-generation. Often the same families were employed in the same mills for three generations.

The Lord Chancellor

The boom period for textiles, in the late 19th and early 20th Century, made many industrialists very wealthy, which can be seen in some of the grand architecture of both the town and its mills. The inhabitants of Huddersfield prospered. Unfortunately, with the decline of business in the early-mid 20th Century, many of the mills, which once clothed the world, now stand silent or have lent themselves to new uses. Those which remain are specialised niche businesses, still continuing the traditions of textile manufacture in a very demanding marketplace. In fact many people now want to know and understand the early skills of woollen manufacture, and how to work with and use wool.